Principle and application of dewaxing water

Principle and application of dewaxing water

Overview [1]

Wax removal water is a kind of industrial cleaning agent, is based on water as a solvent, to the surfactant as an active substance, with a certain function of additives, wax removal water is mainly by reducing the interfacial tension of wax and workpiece, after wetting, penetration, stripping, capacity and other comprehensive process to achieve the removal of wax pollution cleaning. Dewaxing water is a chemical agent used for cleaning hardware workpiece after polishing. It is widely used in the fields of electroplating, clocks, cutlery and craft jewelry.

Classification [1]

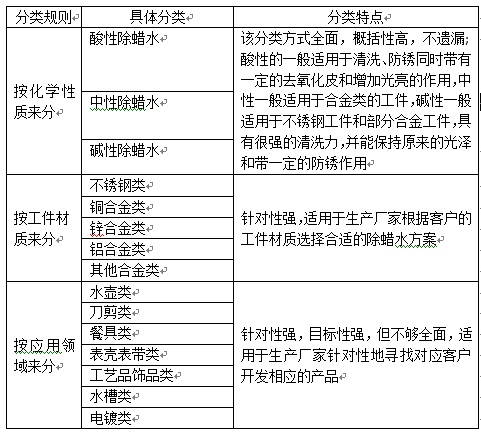

Table 1 shows the classification of dewaxing water

Principle of action [1]

At present, there are few literatures on the dewaxing mechanism of dewaxing water. Most of the literatures show that through the integrated effects of directional adsorption, wetting, emulsification, dispersion and capacity increase of surfactants, and then assisted by cleaning methods such as heating, brushing, spray washing or ultrasonic vibration in the process of dewaxing, the wax dirt can be separated from the workpiece surface more quickly and dispersed into the cleaning solution, so as to achieve the purpose of removing wax and scale.

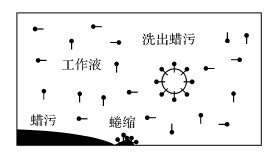

The core mechanism of wax removal is the principle of similar dissolution and the curling mechanism. The curling mechanism of wax removal is shown in Figure 1. A large number of experiments have proved that the cleaning power of paraffin removal water is directly related to the oil-philic group of surfactant. According to the principle of similar phase dissolution, the oleophilic base group of the surfactant can be directly combined with the long chain wax dirt such as mineral oil and stearic acid in polishing wax, and then softened and dispersed in the cleaning liquid with the help of the hydrophilic group, to achieve the purpose of cleaning.

Figure 1 visually shows that the wax stain in the molten state reduces the interfacial tension between the wax stain and the workpiece through the wetting and osmosis of the surfactant, making the wax stain coiled away from the workpiece surface, and then disperses in the cleaning solution through the emulsification and capacity of the surfactant, preventing the small wax stain from reaggregation and readhesion to the workpiece surface, thus completing the cleaning process.

图1 Is a schematic diagram of waxing removal by curling mechanism

Application process [1]

At present, the use of wax removal water on the market can be summarized into hot soaking, ultrasonic hot soaking and automatic line cleaning, hot soaking spray and brush roller automatic cleaning machine four main cleaning processes. What these four processes have in common is that they require heat, but the difference is that they apply external forces in different ways.

(1) Hot soaking. This kind of process equipment needs to be simple, as long as there is a tank to store or heat water, it is mainly suitable for flake workpiece, accounting for relatively small workpiece, but the number of workpiece is particularly large, for example, in the early 21st century Yangjiang, Jieyang and other cities scissors, knives, tableware market especially used. However, due to its slow cleaning speed, the gap holes of the workpiece is difficult to remove, the need for workers to labor operation intensity is larger and there are high risk defects, so that this cleaning process only exists in part of the small workshop demand is not high, some manufacturers also cooperate with other processes used together.

(2) ultrasonic hot soaking and automatic line cleaning. On the basis of hot soaking, the ultrasonic device is added to solve the hot soaking cleaning speed is slow, the workpiece hole is difficult to clean the weakness, has been welcomed by the majority of manufacturers, has become the most common way to use wax water in the market. In the process of ultrasonic cleaning, the workpiece needs to be separated to place the cleaning tank, so it needs a lot of manpower to hang and hang the workpiece, and the matching of hanging tools is particularly many. Therefore, the development of the ultrasonic automatic cleaning line, the workpiece cleaning simplified into a hanging and a hanging, can be called the perfect wax cleaning, basically popular in the Pearl River Delta and Yangtze River Delta hardware processing plants, such as Zhongshan and Zhanjiang electric kettles, Yangjiang knives and scissors, Jieyang watchband and tableware and Zhejiang and Guangzhou crafts and ornaments. However, the production and maintenance of ultrasonic automatic cleaning line equipment needs a lot of money, ordinary small 3 slot cleaning line to tens of thousands, slightly larger, and then equipped with drying equipment to say hundreds of thousands or even millions of, so that it has become some small and medium-sized manufacturers chicken ribs, affecting the use of its promotion.

(3) Hot soaking spray is developed on the idea of solving the problem of wax removal from the holes in the workpiece in hot soaking. That is, after hot soaking, high-pressure hot dewaxing water cleaning liquid is immediately used to spray the surface of the workpiece, so that the wax dirt on the surface of the workpiece is quickly separated and the purpose of improving efficiency is achieved. This process is less than the investment cost of ultrasonic, but also to solve the problem that ultrasonic in-situ vibration is difficult to remove the thick wax caked, so it is often used in some hardware irregular parts factories.

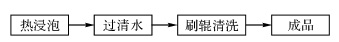

(4) brush roller automatic cleaning machine is gradually mature and promoted in recent years. The main starting point of its process is to clean the workpiece of the plane, which is generally used with hot soaking. The overall technological process is shown in Figure 2.

图2为热浸泡与刷辊清洗机联合使用流程图

Brush roll cleaning machine generally comes with 3 heating sinks, usually 3 slots are hot water, but also to increase the effect of the added cleaning liquid or rust water. Brush roller cleaning machine is mainly concentrated in knife, scissors, tableware and other planar workpiece manufacturers.

Preparation method [3]

Production process:

(1) Firstly, the diethanolamine oleate was mixed quantitatively, and fully stirred at room temperature, and heated to 60℃ at the same time. After cooling, solution Ⅰ was obtained for use.

(2) The quantitative sodium pyrophosphate was added into the water, and the clarified solution Ⅱ was obtained after being fully stirred at room temperature.

(3) Add solution Ⅱ to solution Ⅰ, stir thoroughly, and then add the remaining components in the formula quantitatively, and at the same time heating to 60℃, cooling to room temperature, to obtain the product. In the configuration of steel parts cleaning liquid, add 30 times the volume of water in the above wax removal water, stir well to obtain steel parts cleaning liquid, steel parts cleaning process can be carried out at 65℃ and ultrasonic.

Application [2]

Dewaxing water is widely used in electroplating, watches, crafts, jewelry and other hardware industry after polishing of the workpiece wax removal process.